Introduction

ApplicationStationary generator

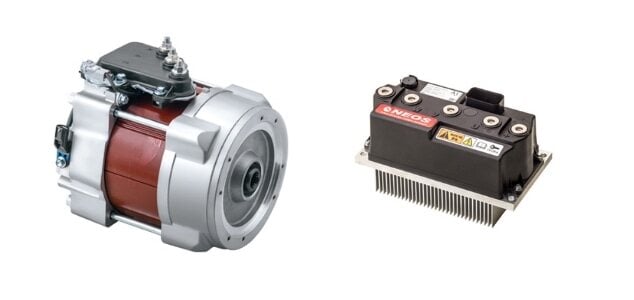

Deployed product: FC Module

The origin of Brother Industries' involvement in fuel cell development can be traced back to Nissei Corporation (hereafter referred to as Nissei), a fully owned subsidiary of Brother Industries. Nissei, which primarily manufactures and sells gears and gear motors, had independently pursued technological development centered on energy themes. Within the research, Nissei paid attention to hydrogen fuel cells and began developing polymer electrolyte fuel cells (PEFCs) in 2002.

When Nissei became a consolidated subsidiary in 2013, technical exchange meetings between the two companies revealed an opportunity to leverage the 10 years of experience and expertise Nissei had accumulated in the fuel cell business. Brother Industries recognized the potential for synergy between Nissei's fuel cell systems and its own diverse resources and decided to transfer the development as a part of new business initiative.

We received many concerns from customers about the image that hydrogen is dangerous and the complicated legal compliance for handling it. Therefore, we adopted hydrogen storage alloys certified as non-hazardous materials, and emphasized that anyone can transport hydrogen safely and securely. These efforts have attracted significant interest and is one of the reasons why our products have been adopted.

In addition, as a power source to be installed outdoors, there were many strict requirements for reliability. In response to these requests, we have conducted verification tests in customer environments and strived to improve quality.

In recognition of these efforts, Narita International Airport Corporation has adopted 84 sets of our ‘AC-UPS series’ as emergency backup power sources. Including the hydrogen filled in the hydrogen storage alloy, it has an expected lifespan of 15 years and can generate power continuously for up to 72 hours*. The Fuel Cell backup power sources is expected to be a means of continuously operating social infrastructure facilities that cannot be stopped.

*Hydrogen replenishment is required for 72 hours of continuous power generation.

Since launching fuel cell sales in 2018, our company has offered relatively low-output fuel cells. In 2023, we began taking orders for a 500W to 1kW class fuel cell system, the 'AC-UPS series'.

We initially focused on low-output products, taking into consideration the challenges associated with hydrogen supply. However, recent years have seen growing interest in hydrogen, with demand emerging across various use cases. This has motivated us to provide higher-output products.

In addition to hydrogen storage alloys, we have achieved long-term power generation and a long life through our unique hybrid control that combines FC modules and batteries. Furthermore, we are developing the next model to be compatible with cold start operation in sub-zero environments. It is one of major advantage from Toyota Industries' FC module that can be used at -20°C.

We are confident that our generators, which utilize fuel cells for the automotive industry and are equipped with FC Module that meet reliability requirements for industrial truck, will be a reliable choice for our customers.

We see significant challenges in the supply chain of hydrogen. Therefore, it is essential for many companies with different applications to work together to consolidate hydrogen demand and secure a supply source, including Toyota Industries Corporation, FC forklifts manufacturer, and Brother Industries, fuel cells generators manufacturer.

Under current regulations, hydrogen stations can only supply hydrogen to certain targets, such as FC vehicles and FC forklifts. The use of hydrogen stations due to deregulation is the most anticipated example. If we can safely use it for much more applications, I feel that the spread of the hydrogen society will definitely accelerate.

As the required specifications differ between forklift and stationary fuel cell systems, we had many discussions to proceed with the development. As both companies are located in Aichi Prefecture, we are deeply grateful that they have been sincerely considering the matter while maintaining very close communication.

Since our target applications are different from those of Toyota Industries', we would like to ask for their cooperation in a wide range of areas in the future besides the supply of FC modules.

Additionally, in the 'Chubu region', which is the central part of Japan, there are activities by the ’Chubu Hydrogen and Ammonia Social Implementation Promotion Council’ and the ‘Chubu Hydrogen Use Council’, attended by many local governments and hydrogen-related companies. We expect Toyota Industries to play a leading role in tackling many issues.