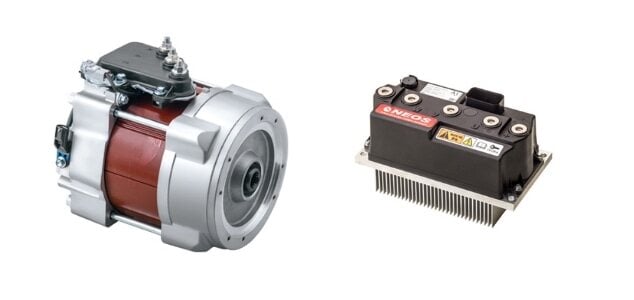

The motor controller is a product that conducts a large amount of current, so with downsized body it will easily cause problem of the heat. Without countermeasures against the heat, the forklift cannot work enough continuously. Therefore, it was mandatory to devise the design how to suppress the heat generation and how to dissipate the generated heat.

Therefore, in designing a MOS FET substrate that outputs motor current, we repeatedly calculated simulation to design an optimized layout for reducing losses. In addition to hardware design we have succeeded in reducing switching loss and heat generation by combining software control. The design of the heat dissipation has been optimized by changing the combination of the size and number of heatsink fins and performing various simulations.

At that time, it was designed by a really small team, so the responsibility of one engineer was very wide, and I myself experienced wide range of work from structural design, board design to overseas part selection.